The Plastic Process: Composite

In addition to our core business, sheet plastics milling, bending and assembling, we have integrated a composite activity.

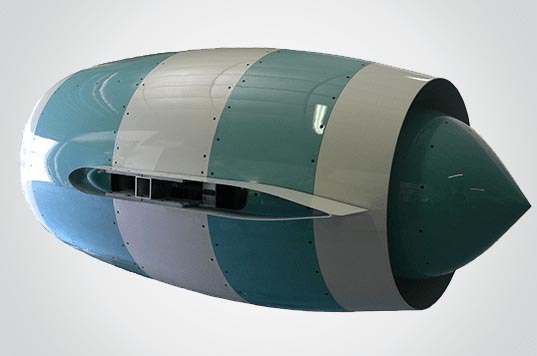

Using the composite manufacturing process, we have carried out various prototype projects for the automotive (Formula 1 car) or aeronautical (fairing for wind tunnel test) industries.