Custom Plastic Enclosures: The Right Choice for Electronics

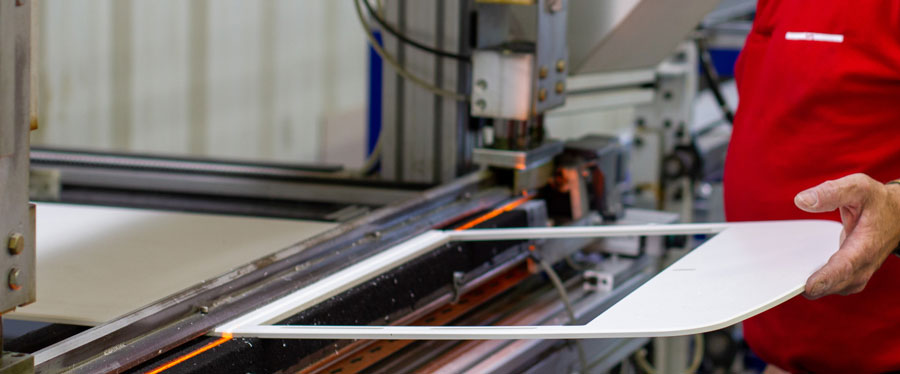

Choosing the right plastic enclosure is crucial for protecting, showcasing and ensuring the compliance of your electronic device. Discover how to compare standard, configurable and fully custom options.