- +33 (0)2.35.54.63.40

- sales@ltp.fr

-

La Tôlerie Plastique ZI Route d'Etretat Impasse des thuyas

76930 Octeville-sur-mer France

In line with LTP’s strategy to control its lead times and quality, finishing operations are integrated into our LTP process.

We carry out 3 types of applications in our workshops: :

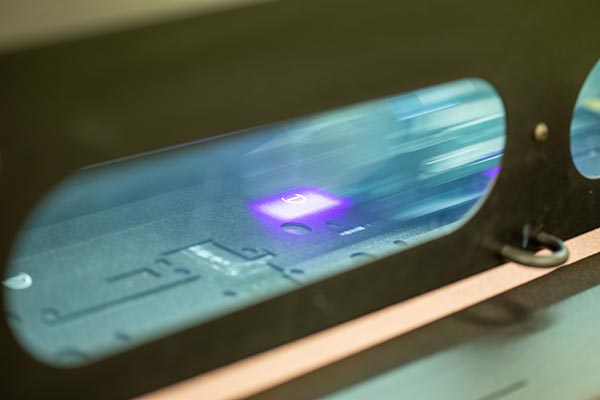

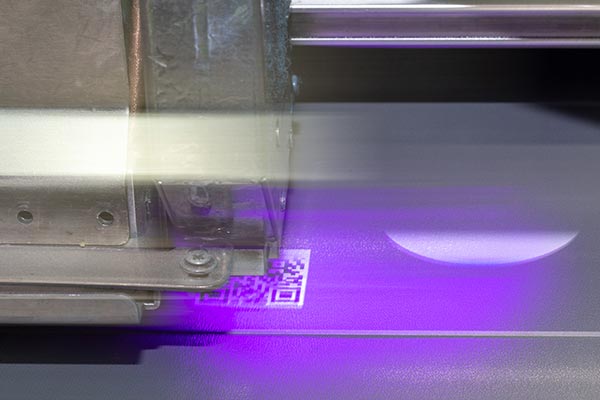

The marking is done on the production line before assembly of the final case or on the finished case after painting:

We can also apply labels made in our finishing workshop.