- +33 (0)2.35.54.63.40

- sales@ltp.fr

-

La Tôlerie Plastique ZI Route d'Etretat Impasse des thuyas

76930 Octeville-sur-mer France

Plastic printing is a term generally used to describe the action of adding a visual (text or image) to an object.

The object can be a container, such as packaging (plastic bottle, plastic bag etc.) or a cover to protect electronic components. Printing on plastic is first used for these different uses to identify the product and add information about the product. Secondly, printing on plastic is used to embellish the object and reinforce the identity of the product or brand.

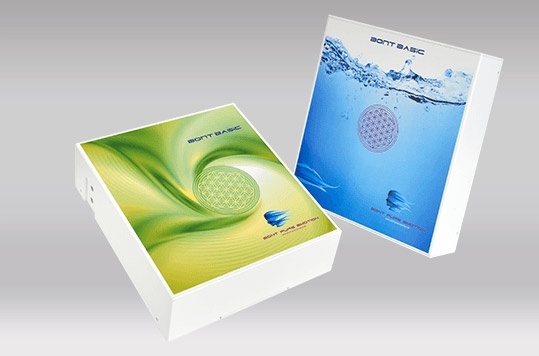

At LTP, we design and manufacture bespoke cases and housings without the need for special tooling. Printing on rigid plastic allows us to create a finish adapted to an electronic device with safety instructions, identification to facilitate connection and also the brand of the device or company.

This finish also makes it possible to adapt the test, analysis or measurement device to its market (Health & Beauty, Industry, Tertiary & Service) to guarantee commercial success.

At LTP plastic printing is the process of digital printing.

« Digital printing is a reproduction technique that allows documents to be printed directly from computer data.»

Wikipedia

Digital printing is, therefore, the opposite of offset or screen printing.

In digital printing methods, a distinction is made between digital inkjet and laser printing. Our workshops are equipped with 2 inkjet printers. This equipment enables us to mark on your plastic cases entirely to measure, even for small and medium-sized series. This method is fast, flexible and above all, economical.

Take advantage of the complete LTP offer for the keyboard or accessory part to finish your customised case or plastic part developed for your device. Our teams can also create your visual from your logo, text and colour codes. This flexibility allows you to concentrate on the development of your device.

It is also possible to modify your visual between series. Has your marketing department changed your company’s graphic design? Are you a company manager who wants to modernise your corporate identity? No problem with your plastic marking. Simply send us the information, and our plastic marking service will make the changes and send you proof for validation.

Give us a call +33(0)2 35 54 63 40.

Let's talk about your project to find the right solution. Our teams are at your service.