Custom Plastic Enclosure Pricing: The Complete Guide to Estimating Your Budget

Discover how to estimate the cost of your custom plastic enclosure. From prototype to production, learn what influences the price and how LTP enclosure technology helps.

Enclosures

Discover how to estimate the cost of your custom plastic enclosure. From prototype to production, learn what influences the price and how LTP enclosure technology helps.

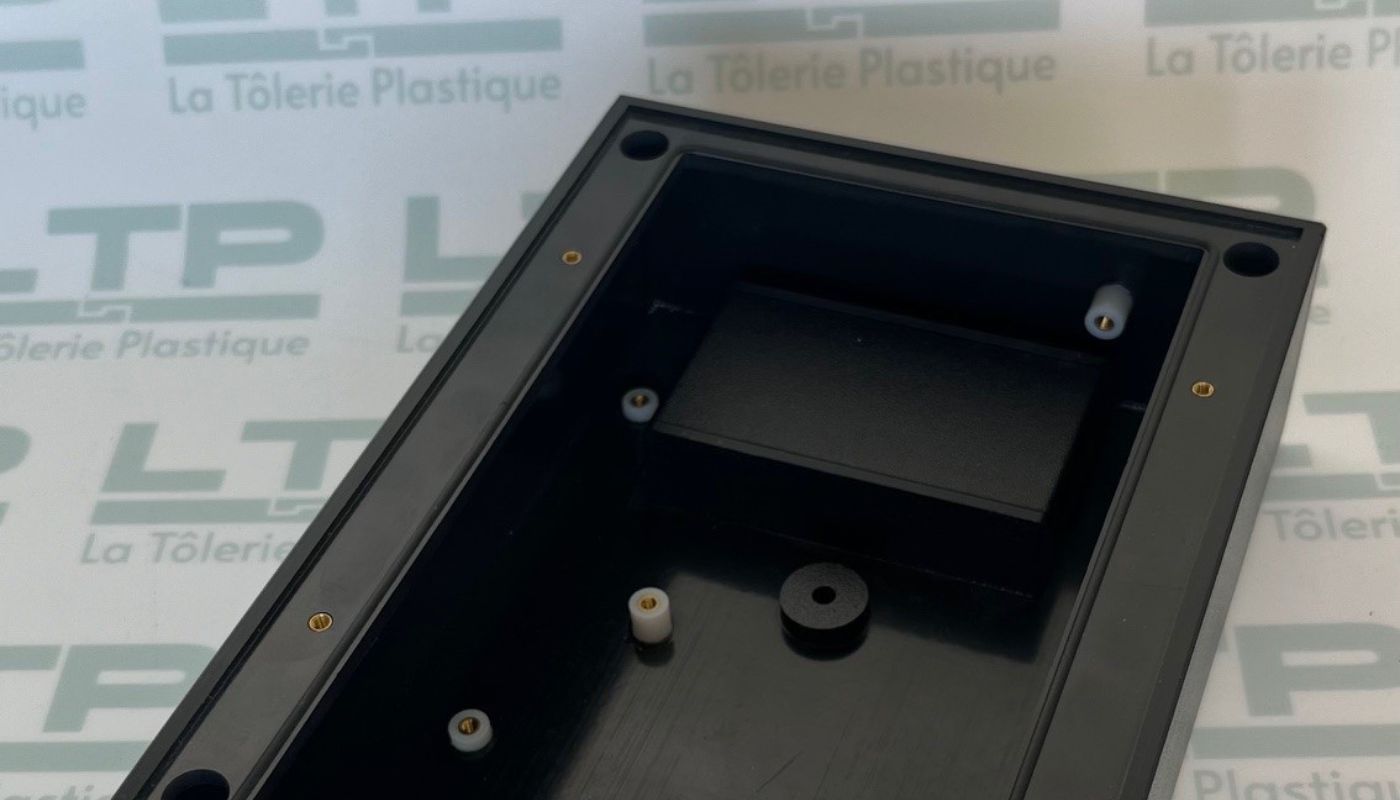

A functional prototype made with LTP enclosure technology lets you validate design, test mechanics, and secure your series production with the exact same material, process, and finish.

At LTP, every custom plastic enclosure undergoes a rigorous final quality control before shipment to guarantee compliance, mechanical reliability and aesthetic perfection for electronic, medical and industrial applications.

Standard plastic enclosures are quick and inexpensive but soon show their limits. Discover why mould-free custom plastic enclosures from LTP are the flexible, cost-effective solution for your electronic projects.

Designing a plastic enclosure for an electronic system? This article answers the 10 most frequently asked questions about custom plastic enclosure design using LTP enclosure technology — a mould-free solution for small and medium production runs.

Choosing the right plastic enclosure is crucial for protecting, showcasing and ensuring the compliance of your electronic device. Discover how to compare standard, configurable and fully custom options.

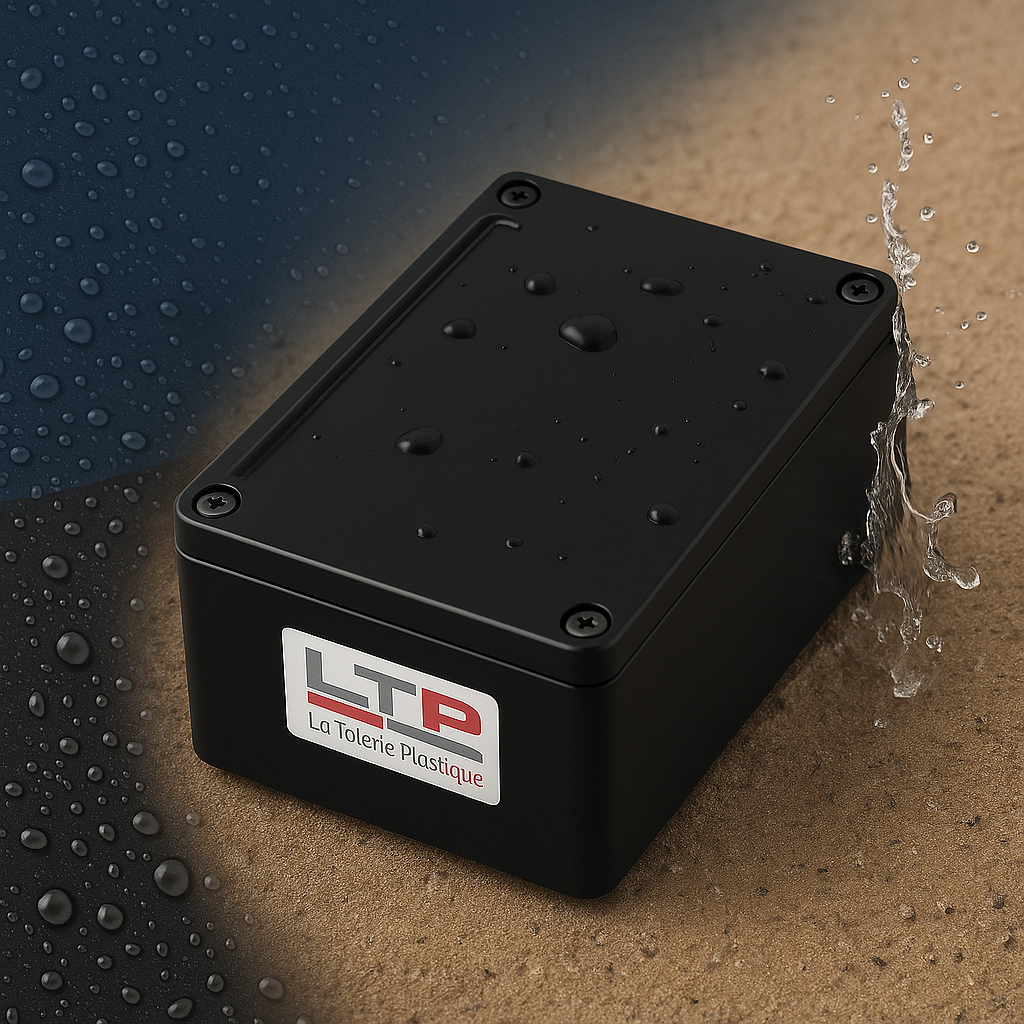

Need a reliable enclosure for outdoor electronics? Learn how LTP provides mould-free custom solutions with IP65 protection.

Custom plastic enclosures for green spaces and living walls: cost-effective, flexible, and sustainable solutions for architects and construction projects.

Discover our custom plastic housing solutions for industrial optical sensors. Guaranteed precision and protection with LTP.

How do you design a bespoke plastic enclosure that meets IP65 standards? Waterproofing, choice of materials and optimised design thanks to LTP.