At LTP, every project ends with a crucial stage: the quality control before shipment.

This phase is essential to ensure the compliance, reliability and aesthetic quality of every custom plastic enclosure designed using our mould-free process.

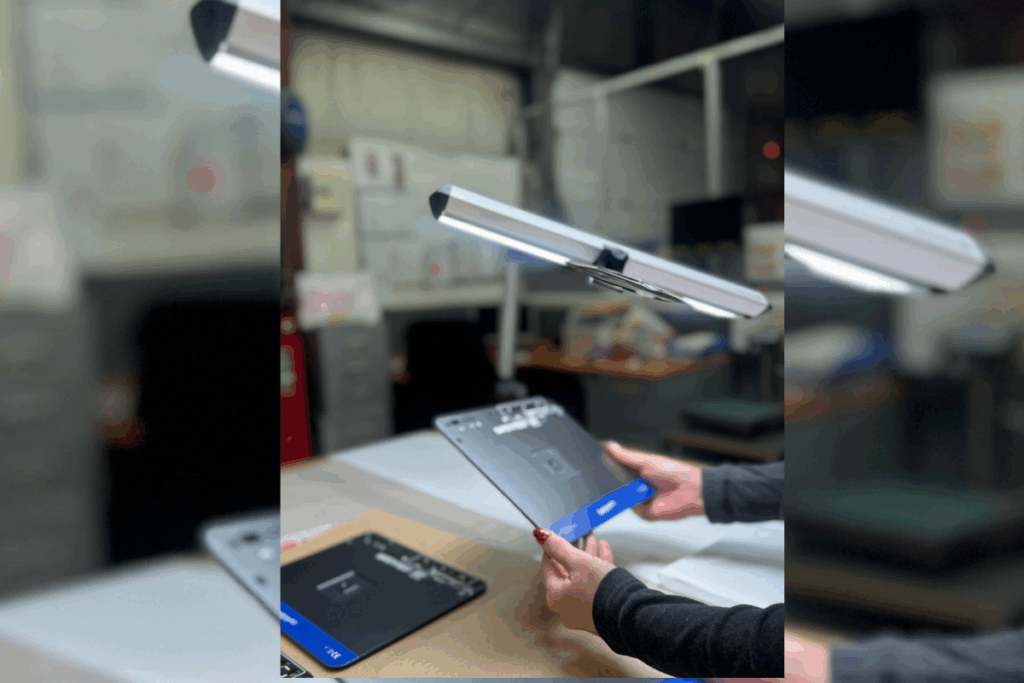

Before leaving our workshops, each enclosure is handled by experts to guarantee its compliance and its ability to integrate seamlessly into its electronic environment.

Why is this step crucial?

When manufacturing enclosures for electronic, medical or industrial equipment, compliance with technical specifications is mandatory.

A misplaced hole, an incorrect fit, or a missing part can block an entire assembly. A surface defect can lead to rejection or customer dissatisfaction.

The Final Quality Control Process:

The final inspection is the last stage of the quality process that follows the enclosure from order entry, through design, and throughout production.

This final check ensures:

- Dimensional compliance with the validated 3D plan,

- Proper mechanical assembly of all components,

- Visual quality of all visible surfaces.

How does LTP ensure compliance before shipment?

Each batch undergoes a final inspection based on an internal checklist to confirm the conformity between the validated 3D design and the finished product.

Our teams verify that all intermediate checks have been carried out, and inspect the critical dimensions, visual appearance, subassembly alignment, and cleanliness of the surfaces.

- Visual inspection aims to detect any surface anomaly: scratches, glue marks, inclusions or other defects.

The operator also ensures that all elements are in place: inserts, windows, seals, labels or functional accessories. - Functional dimensions are checked during machining using appropriate measuring tools such as callipers, gauges or rulers, on a defined sampling basis. In some cases, when specified by the client, a final dimensional check using dedicated gauges is carried out before shipment.

These inspections guarantee the precision of drillings, the alignment of cut-outs, the proper fit of subassemblies, and the structural stability.

Mechanical assembly is verified: fitting, screwing, bonding, opening and closing of covers, and wall stability.

Any non-conforming part identified never leaves the workshop. It is returned to production for correction (paint retouching, re-bonding, or replacement).

Each reworked part is reinspected before reintegration into the batch.

Quality extends to packaging:

The choice of packaging is also defined according to the enclosure’s specific characteristics and recorded on the production sheet.

Depending on requirements, the products are protected by bubble wrap, foam, skin film or custom packaging.

These precautions ensure that the products arrive intact, clean and ready for integration.

Result: upon delivery, the customer receives parts ready for assembly.

Conclusion:

At LTP, quality control before shipment is not a formality — it is a commitment: to deliver products that are compliant, clean and protected.

This level of demand is part of our overall quality approach, serving your electronic, medical or industrial projects.

It’s our way of assuring you that your project is in good hands.

Let’s talk about your project!

Phone: +33 (0)2 35 54 63 40 | Email: sales@ltp.fr