In the design of electronic systems, the enclosure is not just an accessory: it protects, enhances, and determines the performance of your components. Many companies first choose a standard plastic enclosure, readily available in catalogues. However, this solution quickly reaches its limits when requirements become more specific.

Why not limit yourself to a standard plastic enclosure?

The advantages of a standard plastic enclosure:

A standard enclosure remains attractive in certain cases:

- Fast delivery: mass-produced, it is available without delay.

- Low unit cost: ideal for simple requirements.

- Ease of access: perfect if your components exactly match the proposed dimensions.

Source: BOPLA – Enclosures that dress and protect your electronic systems | English

The limits of a standard enclosure:

As soon as your requirements evolve, challenges arise:

- What if your electronic boards do not fit into the predefined size?

- How can you add ventilation, a cut-out, or a specific connector?

- Will your enclosure adapt if your components change over time?

- How do you ensure ergonomics adapted to the end user?

These limitations show that a standard enclosure is often a short-lived compromise.

Why choose custom mould-free solutions?

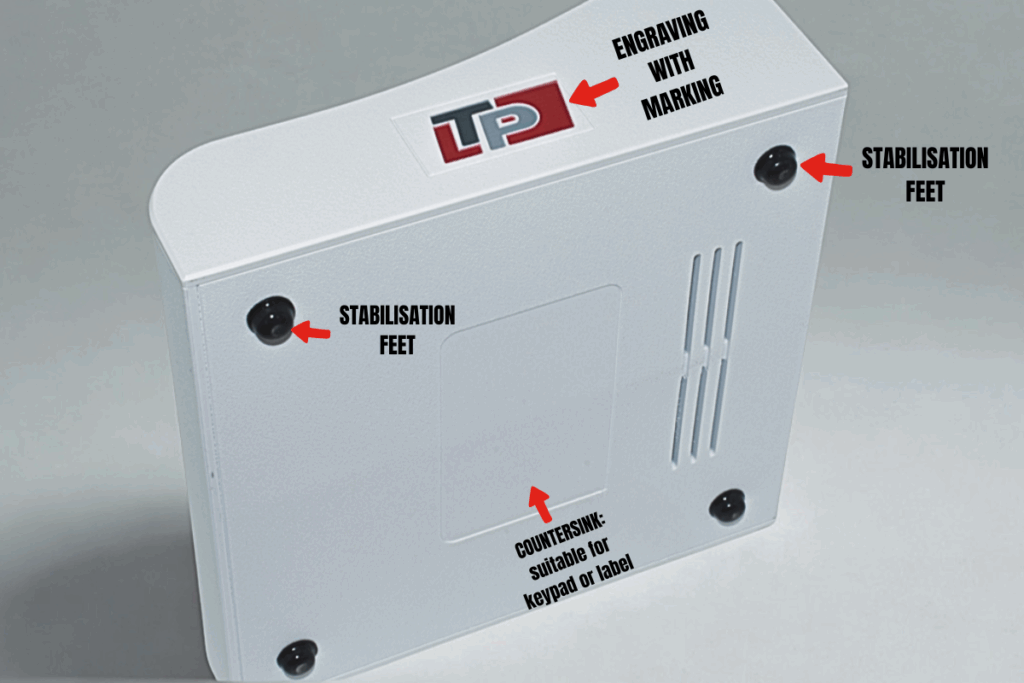

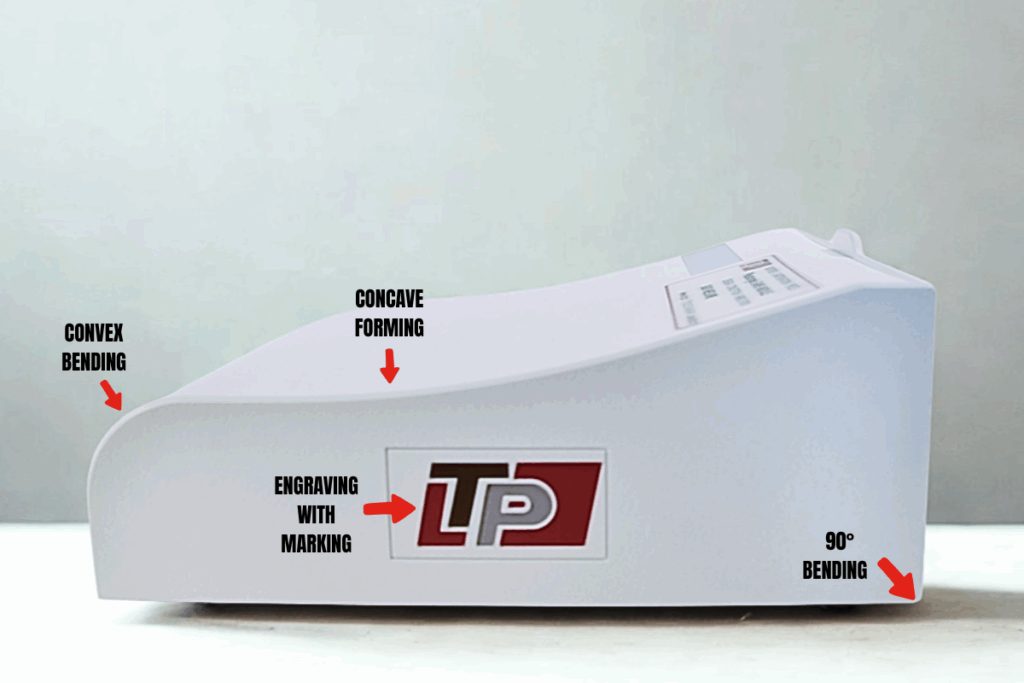

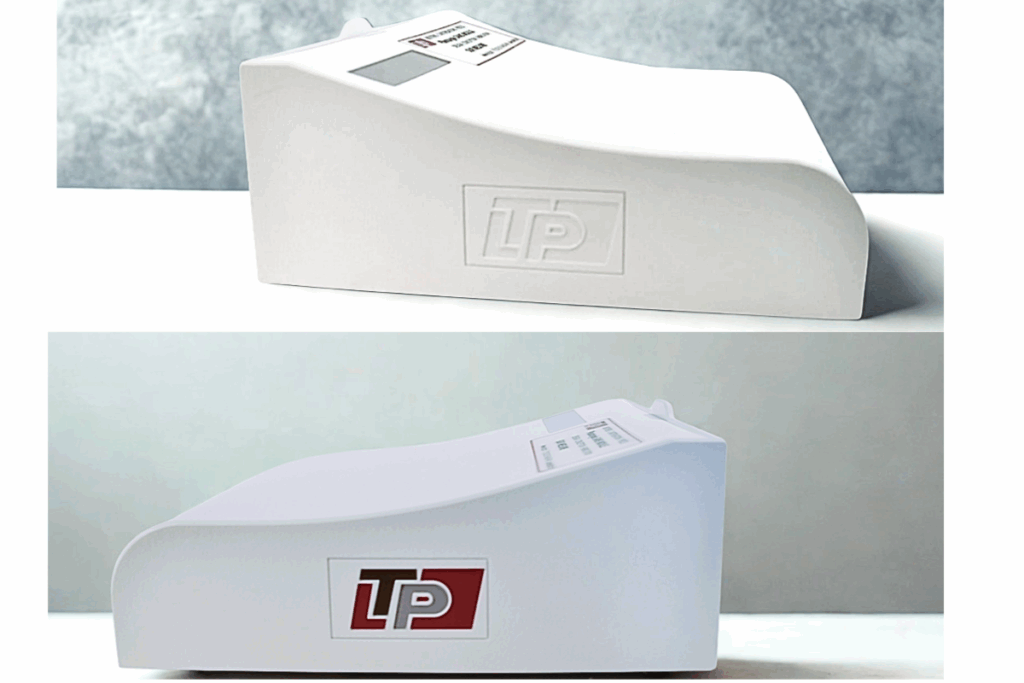

With the plastic folding and machining technology developed by LTP, you benefit from enclosures perfectly adapted to your needs:

- Custom design: ventilation, push-outs, marking, ergonomic design.

- Flexible production: from 5 to 5000 units, without moulding constraints.

- Agility and savings: no heavy investment in tooling.

- Lead times of 4 to 6 weeks

Unlike an “off-the-shelf” option, a custom mould-free plastic enclosure adapts to your project in every detail. Do you need a specific internal mounting? A cut-out for your external connectors?

A suitable ventilation system or a wall mount? All this is possible, quickly and without additional mould-related costs.

A custom enclosure ensures a product designed for your components, not the other way around. By contrast, a standard enclosure imposes its limits: fixed dimensions, lack of flexibility, difficulties accessing connections… Constraints that sooner or later become a barrier.

At LTP, we make it a rule: “it is the enclosure that adapts to the electronics, not the other way around“

The mould-free custom plastic enclosure is the ideal solution to support your electronic projects, from prototype to series: Preconfigured plastic enclosures to customise or 100% tailor-made

Contact us today to discuss your custom enclosure requirements and discover our innovative solutions.

Telephone: +33 (0)2 35 54 63 40 | Email: sales@ltp.fr