As part of a rehabilitation project, integrating electronic components into outdoor or exposed environments raises a key question: how can their reliability be ensured against humidity, dust, and weather?

This is where the enclosure’s sealing level becomes critical.

Unpredictable outdoor environments

Outdoor applications include installations in unprotected areas: façades, rooftops, open technical rooms, or green spaces. In such conditions, electronic enclosures are exposed to:

- Dust and airborne particles,

- Ambient humidity, water jets or rain,

- Significant temperature variations.

To ensure their durability, it is essential to rely on IEC 60529 standard, which defines protection levels for enclosures against the ingress of solids and liquids.

This is referred to as the IP rating, or Ingress Protection.

This code is written IPXY, where:

- X indicates protection against solid objects (dust, particles, etc.),

- Y indicates protection against liquids (drips, splashes, jets, etc.).

For example, an IP65 enclosure means:

- 6 = complete protection against dust

- 5 = protection against water jets from all directions

- Source IEC 60529 standard: IEC Webstore – Standard IEC 60529

For a simple presentation of IP ratings: Wikipedia – IP Code

The LTP process: custom enclosures, mould-free, with IP65 sealing available.

At LTP, we offer an industrial and flexible tailor-made solution without any mould:

✔️ No upfront investment: ideal for small and medium production runs (from 10 units)

✔️ IP65 sealing available on request thanks to specific design with foam or silicone gaskets, screw or clip closures

✔️ Customisable shapes: connectors, cables, specific fixings, etc.

✔️ Finishing options: painting, marking, engraving, integrated drilling

✔️ Fast turnaround: between 2 to 6 weeks depending on complexity

Our materials comply with REACH, RoHS, and are available in flame-retardant versions (UL94-V0).

Real-life outdoor examples: two IP65 applications

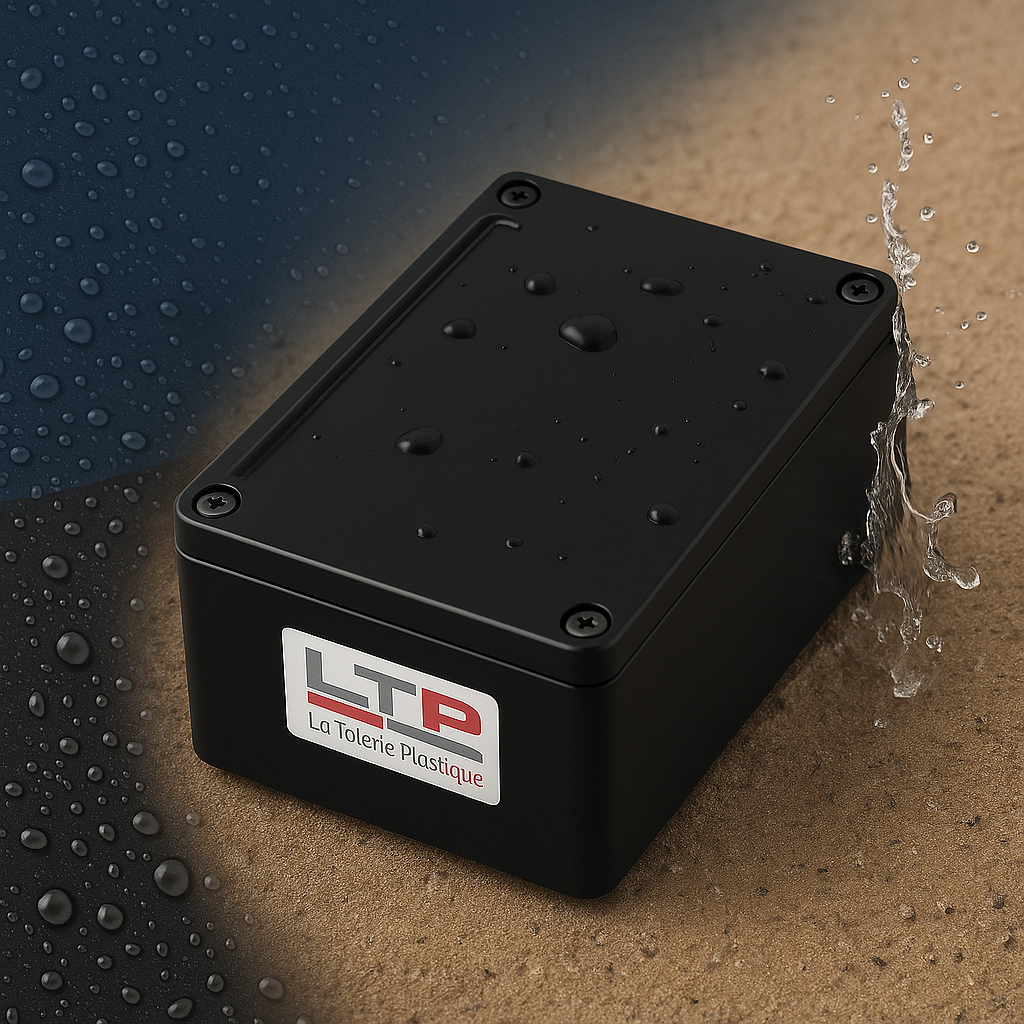

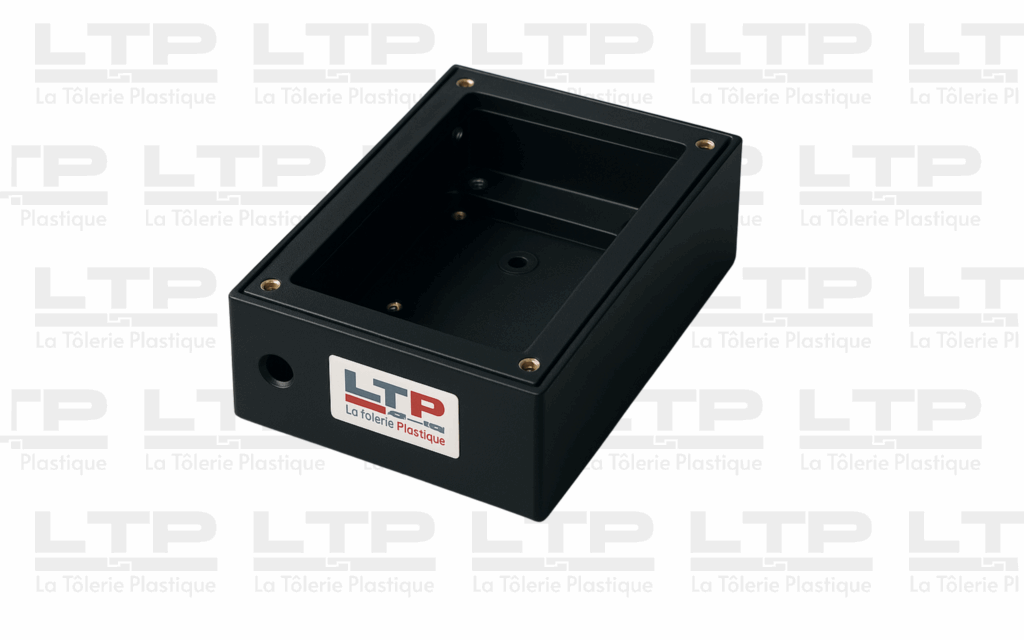

Technical enclosure for battery and power electronics – IP65

This enclosure is made of black UL94-V0 ABS, a rigid, lightweight, flame-retardant plastic.

It was designed to house a battery module in a semi-open environment, with occasional exposure to humidity and dust.

✅ Made from UL94-V0 fire-rated ABS

✅ IP65 sealing ensured by compressed foam gasket

✅ Brass inserts for internal mounting

✅ Custom machining for embedded electronics

IP65 enclosure for car park access control – outdoor use

This outdoor enclosure is made of painted PMMA and ABS, an aesthetic and UV-resistant material, suitable for public-facing environments (terminals, access points, façades).

It integrates an RFID reader in a car park access control terminal.

✅ Materials: PMMA and ABS with polyurethane paint

✅ IP65 sealing

✅ Custom design with functional rounding

✅ Coloured finish in line with client branding

Why choose LTP for your electronic enclosures?

With LTP, you benefit from a solution tailored to your field requirements, without compromising on reliability, flexibility or lead time.

Our exclusive LTP enclosure technology offers a fast, customised and cost-effective solution, even for complex or non-standard projects.

📞 Contact us today to discuss your bespoke enclosure requirements and discover our innovative solutions.

📞 Phone: 0033 (0)2 35 54 63 40 | 📧 Email: sales@ltp.fr